You've probably heard of 3D printing. This manufacturing process, which involves printing an object layer by layer, is now considered the fourth industrial revolution. Initially used for rapid prototyping, additive manufacturing has made significant strides in less than two decades. Let's take a closer look at this innovative technology that will significantly transform the future of our world.

What is 3D printing?

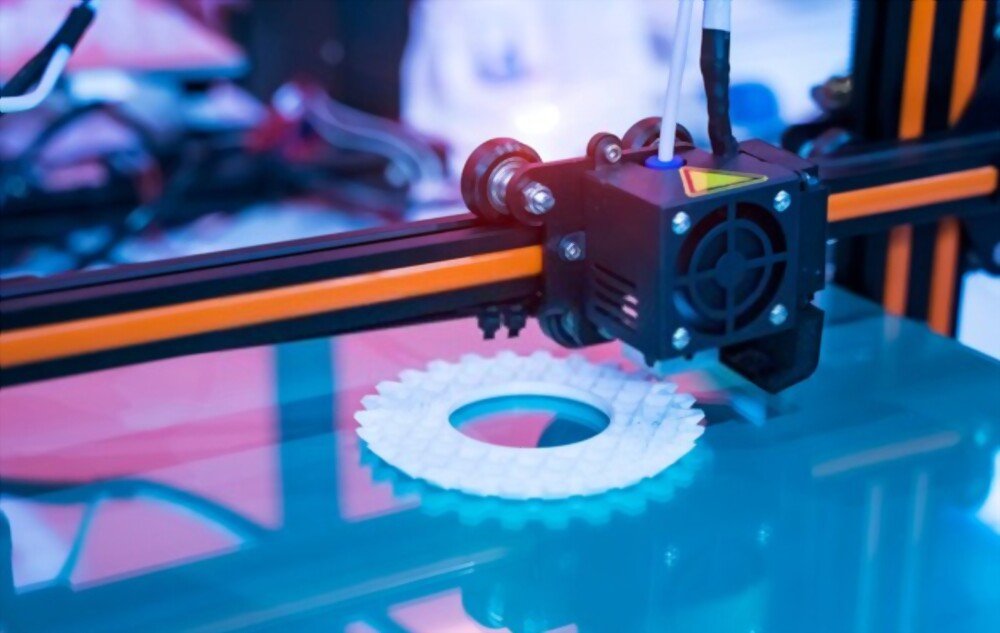

3D printing is another name for additive manufacturing . This process refers to a method of designing and manufacturing objects layer by layer. The industrial, automotive, technical, and aerospace sectors are where this production method is most frequently used. Unlike subtractive manufacturing, 3D printing allows for the creation of objects based on a model created as a 3D file.

Specialized software is used to slice the object into multiple layers. These layers are then assembled. The assembly and solidification of the different layers are achieved using a 3D printer to obtain a finished product. The part is created by combining all the layers.

Additive manufacturing emerged around 2000. At that time, it was used for rapid prototyping. Technological advancements have since enabled the development of a wide range of possibilities for both the size and shape of the parts produced. Various materials such as plastic, plaster, metal, WPC, and fiberglass have allowed manufacturers to create parts in different production runs.

These materials are also used to produce parts for surgery, aerospace, and many other fields. Examples include the production of models, luxury goods, jewelry, prostheses, implants, houses, and even everyday accessories. 3D printing can offer high-quality design and a refined finish thanks to its innovative features.

What advantages does 3D printing technology offer?

The speed of execution is one of the main advantages of additive manufacturing. Now, thanks to CAD software, you can do without the expertise of the numerous engineers you previously needed to assemble to design any object or part. The various stages of manufacturing an object are now completed in a very short time. Thus, 3D printing offers time savings that positively impact the productivity of businesses.

In industrial plants, the use of additive manufacturing has led to an acceleration of work processes. Furthermore, 3D-printed parts offer excellent value for money. Indeed, 3D printing makes it possible to produce high-end products at low cost. The immediate consequence of this is the optimization of time to market.

Precision in object design is another hallmark of 3D printing. 3D models form the starting point for product manufacturing. It is from these models that the printer reproduces the details and characteristics of each part. The absence of manufacturing defects is another advantage offered by this production process.

Engaging the expertise of a 3D printing company guarantees meticulous, high-quality work. These companies possess highly efficient equipment and personnel, allowing you to benefit from local service and personalized support. Using various printing processes such as beam melting, material extrusion, and laser sintering, 3D printing companies will bring your project to life.

What are the steps involved in creating a 3D object?

As mentioned in the introduction, additive manufacturing is a process for creating objects using a 3D printer. Creating a product involves several steps, from the initial 3D design using CAD software to the post-processing stage. STL conversion, file manipulation, the actual printing process, and support removal are all transitional steps.

Additive manufacturing begins with the design of a digital prototype. This step relies on a method called CAD (Computer-Aided Design). After its design, the CAD file is then converted into an STL file. This conversion differs depending on the type of technology used. The role of the STL file is to define the surface of an object by subdividing it into several triangles or polygons.

3D printing is the third stage of additive manufacturing. 3D printers are made up of many small, highly complex parts. These parts ensure optimal precision of the printed product. Obtaining a high-quality print depends not only on the materials used but also on their quality.

With some 3D printing technologies, removing supports is as simple as removing the printed object from the build plate. However, other, more professional methods involve a highly technical process. Post-processing procedures vary depending on the printer type and printing method used.